Ved gennemgang af forskellene mellem den sammensatte skæring og tværgående alt-i-en-maskine og de to fristående maskiner-den sammensatte maskine og den skæringsskårende maskine-kan vi tydeligt forstå deres strukturer og applikationer ved at se på deres konfigurationer og behandling af arbejdsgange.

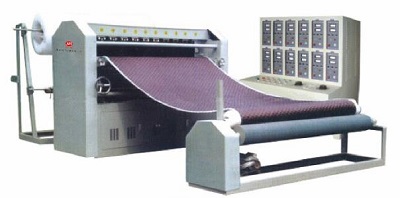

De Sammensætning og tværgående alt-i-en-maskine er designet som en meget integreret løsning. Dens typiske struktur inkluderer:

Dobbelt- eller flerlagsafviklingsstande

Sammensat hovedenhed

Elektrisk kontrolskab

Driftspedal

Slæden enhed

Yderligere fodpedal med spændingsbjælke

Tværgående enhed

De Sammensat maskine derimod består af:

Flerlagsafviklingsstande

Sammensat hovedenhed

REWINDING UNIT

Elektrisk kontrolskab

De Slit og tværgående maskine inkluderer typisk:

Afviklingsenhed

Driftspedal

Slipper hovedenhed

Yderligere fodpedal med spændingsbjælke

Tværgående hovedenhed

Fra denne sammenligning er det tydeligt, at den alt-i-en-maskine konsoliderer funktionaliteterne af begge fristående maskiner i et enkelt strømlinet system.

Når alt-i-en-maskinen er opdelt i to separate maskiner, kræver hver enkelt en yderligere strukturel sektion for at fungere uafhængigt, såsom dets eget kontrolskab eller platformkomponenter. Denne strukturelle redundans øger de samlede udstyrsomkostninger. Derfor fra et prisfastsættelse er den alt-i-en-maskine generelt mere omkostningseffektiv end at købe den sammensatte maskine og skæringsmaskine separat.

Derudover tilbyder den alt-i-en-konfiguration betydelige besparelser i fabriksgulvplads, arbejdskraft og materialehåndtering. Da materialer behandles kontinuerligt inden for en maskine, minimerer det overførselstid, reducerer mellemliggende materialetab og forenkler arbejdsgangen.

Det er dog vigtigt at bemærke, at ikke alle materialer eller produktionsprocesser er egnede til en alt-i-en-løsning. Nogle specifikke produkttyper kræver muligvis separate behandlingstrin eller tilbyder kontrol af bedre kvalitet, når de håndteres af uafhængige maskiner. Desuden er ikke alle kunder vant til eller foretrækker integreret udstyr.

For nogle klienter er fleksibilitet og tilpasningsmuligheder, der er tilgængelige med standalone maskiner, mere ønskelige, især når man arbejder med forskellige materialer eller i indstillinger, hvor separate kvalitetskontrol er kritiske på hvert trin.

Den sammensatte skæring og tværgående alt-i-en-maskine tilbyder en strømlinet, rumbesparende og omkostningseffektiv løsning til mange industrielle applikationer. Ved at integrere flere funktioner i en enkelt enhed forenkler det produktionsprocessen og reducerer de samlede investeringer. Imidlertid bør beslutningen mellem at bruge en alt-i-en-maskine eller separate enheder være baseret på produktets specifikke behov, produktionsmiljøet og kundepræferencer. Forståelse